My account

V-TEC feed wheel John Deere H415/H425 BBR Wide Multispeed

Product price

1 072,14 € / pc

Price including VAT 24% is 1 329,45 €

- Availability

- In stock

- Phone

- +358 561 069 00

- mense@mense.fi

Specially designed for better handling of larger tree trunks and multi-tree processing. The extra wide gripping surface gives better support for the timber.

A wide V-TEC steel feed wheel for John Deere H415 and H425 harvester heads with Black Bruin Multispeed fastening.

| Technical specifications | |

|---|---|

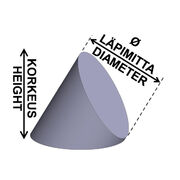

| Measurements | 447x447x156 mm |

| Mounting | 5 bolts |

| Weight | 31 kg |

| Left and right wheel identical | |

| Product code (SKU) | VTJD-415-BB-W |

High quality V-TEC feed wheel designed with customer feedback in mind and it's structure is patented.

Uniquely designed and listening to user feedback

Development work by MenSe Oy on the durable V-TEC feed wheel John Deere H415/H425 BBR Wide Multispeed was accomplished by listening to feed roller users and grab designers. The development work has resulted in a new solution, the V-Tec roller, which has even better grip and is cleaner. At the same time, damage to the wood surface is reduced.

Comparing the V-TEC to standard feed wheels and showcasing it's unique capabilities.

User experiences of the V-TEC feed wheel

Ponsse H6/H7/H8 V-TEC

"These feed wheels provide new features for the grapple. Excellent grip. Pine bark passes through the fingers and the grip is maintained. Working with birch became easier and making tree tops is done better. The biggest difference was noticed when working with big trees and birch. These will also be used in the future."

Ponsse H6/H7/H8 V-TEC

Ponsse H6/H7/H8 V-TEC

"Intelligent ones! Compression pressure can be dropped intelligently, 90 reduced to 70. The feed speed increased. It immediately picks up the wood. Only small marks remain on the tree = does not break the bark. I liked it!! Not noisy. Goes smoother than the previous spike rollers. It's silly to be stingy with the rollers. The money was not wasted."

Ponsse H6/H7/H8 V-TEC

"MenSe's service is fast.

We already have V-tec feed wheels in several machines. We have liked these wheels. We got a new machine now and immediately switched to V-tec.

V-tec cleans well. Bark does not accumulate. Interlaced ribs center the trunk upwards, it does not fall down. The wheels center the trunk to the bottom of the grapple. Good traction. No slipping. Does not damage the surface, so no harvesting damage.

All wheels wear out over time. They are not eternal. However, V-tec wheels can be sharpened/restored, so the lifespan increases. In addition, Ponsse 6-8 Vtec can be reversed. The outer spikes are new twice."

Halkia, Pornainen

Ponsse H6/H7/H8 V-TEC

"We bought our first V-tec feed wheels in September 2019. We have also used original feed wheels occasionally. Our logging sites in Ilomantsi are mainly in Finnish swamps. The average diameter of the trees is only 120cm. They are long and "thin" trees. The feed wheels have accumulated more kilometers in terms of distance than on the thickest sites. When you do windthrow logging under the snow, the feed wheels are exposed to, for example, contact with rocks due to the motion range of the grapple. The V-TEC feed wheel is easy to maintain. The worn blade could be sharpened to its former state even in the forest. The open structure of the feed wheels prevents them from clogging, which is a plus. Reversing is also successful. So, I will order new V-TEC feed wheels for the Scorpion on March 31, 2021"

Ponsse H6/H7/H8 Multi-Tree V-TEC

"I often have projects where I process both energy wood and timber at the same time.

The V-tec multi-tree wheel works well for both. It would be difficult if I had to change wheels when working with different qualities.

When comparing the V-tec to other feed wheels I have used before, the GRIP is very good when operating at normal pressures. They don't slip. In our area in Northern Savonia, the spruce trees are lush and especially the tops are difficult to handle. I got frustrated with regular wheels getting clogged. V-tecs never lose grip and they also don't get clogged. At first, I was afraid that the sharp spike of the V-tecs could cause damage to the logs. The deflection has been measured and it was not a problem. The spikes touch the trunk over a large area, so it doesn't sink into the wood. The wood is not blocked if the V-tec causes damage to it."

Log Max 4000 V-TEC

"I am very satisfied. I have had the Log Max 4000 with Mense-V-tec feed wheels for about two months. The feed wheels run smoothly, have a good grip, and stay clean if it is below -20C. In freezing temperatures, the snow freezes from the side of the flange towards the grip due to the heat. However, it does not affect the grip and it is not a problem."

Ponsse H6/H7/H8 V-TEC

"Incredible grip. The most noticeable difference compared to previous wheels is that the tops go through intact. Feeds well forwards and backwards. Makes calibration (pruning) easier because the surface of the wood remains smooth compared to spiked wheels."

Ponsse H6/H7/H8 V-TEC

"We have had two years - about 5000h V-tec feed wheels on Ponsse.

They have held up well. I initially lowered the compression pressure by 10 bars. Good traction. Sharp and easy to sharpen with a grinder.

There is no going back to spike rollers. I also want V-tec feed wheels for another machine.

We also do some multi-tree handling. Occasionally, branches get caught on the sharp edge spikes of the V-tec feed wheel. Perhaps I will purchase V-Tec multi-tree wheels for these work sites."

John Deere H413 V-TEC

"You have really succeeded with the V-TEC feed wheels. They work perfectly in multi-tree processing and roll smoother than rubber-coated steel wheels. So we are really satisfied!"

Ponsse H6/H7/H8 V-TEC

"Since 2017, we have been using V-Tec feed wheels in Ponsse's 5, 6, and 7 harvester heads. The contractor complained about the damage caused by so-called sea pine spikes. At that point, we decided to test MenSe's V-tec wheels, which were still in the development phase. In collaboration with the manufacturer, we made fine adjustments to them. The contractor measured the deflections and approved the work result.

Compared to the spike and so-called standard straight rib feed wheel, we have noticed that the traction of the V-tec wheel is excellent. There is no slippage with V-tec wheels. The standard wheels slip at the base of the pine tree and cannot be driven twice because the surface is damaged. In short, the advantages of V-tec from our perspective: Traction, reverse capability, can be driven from both sides = wheels are reversible and do not cause harvesting damage."

Komatsu C93 V-TEC

"I should've ordered these two years ago. Huge difference on grip and performance.

One hell of a change

- Power increased

- Winding trees goes through smoothly

- Harvester head is more silent

- Able to decrease gripping pressure

- Excellent grip

- Big or small trunks without a problem

- Cheap price

- Seals do not freeze (open structure prevents water from accumulating)"

Nisula 500H V-TEC

John Deere H415/H425 Black Bruin V-TEC Wide

John Deere H413 V-TEC

"Very good grip. Does not damage the log. Good durability -> driven almost 8000 h. Holds well in both directions. The ribs interlace and in the beginning they round off. No disadvantages have been noticed. Does not clog. Compression pressures lower than when using normal spike rollers. DOESN'T SHAKE"

What are V-TEC feed wheel John Deere H415/H425 BBR Wide Multispeed benefits?

The gripping surface machined onto the diagonal shank in the direction of the axle forms a circular outer sphere, which feeds timber evenly. Cutting length is achieved faster, the operation becomes more effective, improving profitability. The spikes on the diagonal shank provide sturdy support for the timber. The rollers provide excellent grip in both feeding directions, backwards and forwards. The grip also minimizes surface damage. Gripping pressure may be lowered, which also provides savings in fuel costs. Uniquely designed V-TEC feed wheel John Deere H415/H425 BBR Wide Multispeed has an open, light and non-clogging structure. The rollers are made of hard, abrasion resistant steel but still it's weight is only 31 kg.

Cost-effective and long-lasting feed rollers

MenSe feed wheels are for You who appreciates long lifetime with low costs and financial benefit enabled by increased uptime. The warranty period covers 2000 working hours or 1 year.

Article about feed wheels (Koneviesti 16/2017)

The properties of the V-TEC roller are described in Koneviesti magazine (no. 16/2017). Read the article by clicking the image below.

Feed wheel renovation can be done quickly and efficiently with renovation service. The hassle-free service brings additional operating hours to used feed wheels.

Looking for used feed wheels? We also have factory refurbished feed wheels in our selection.

Mense Oy has been manufacturing feed wheels since 1994

Most interesting products

Most popular products on the category and products you might find interesting.

Recommended categories

Hand selected product categories what you should check out.