My account

- You are here: Homepage »

Cutter RP10L

Product price

229 503,34 kr / pc

Price including VAT 24% is 284 584,14 kr

- Availability

- In stock

- Phone

- +358 561 069 00

- mense@mense.fi

| Technical specifications | |

|---|---|

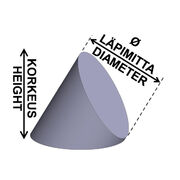

| Working width | 240 cm |

| Max. cutting diameter with one cut | 10 cm |

| Max. cutting diameter by sawing | 15 cm |

| Required oil flow | 130-150 l/min |

| 3/4" G (BSP) | 2 pcs |

| 1/4" G (BSP) | 1 pcs (drain line) |

| Max. pressure | ~ 200 bar |

| Weight | 520 kg |

| Dimensions | 260x71x50 cm |

| Product code (SKU) | RP10L |

| If you order the RP10L cutter without any accessories, the delivery will include a free mounting plate the size of the cutter motor top. |  |

Accessories

When a MenSe cutter is installed to a suitable base machine, a perfect pair for work is being born. The RP10L suits best basic machines of 15-20 tn (oil flow 130-150 l/min).

APPLICATIONS

The cutting is safe for the user and the environment, since no debris is launched ino the air. It is possible to safely work in the city centers and near cars and residential areas, for example. With a cutter equipped with a rotator and tilting adaptor it is possible to cut various different shapes and, selectively, individual branches, for example. Depending on the driver, the cutter can produce very precise and neat work The hedge cutters are used for the clearing of power lines, railway and road sides, sapling stands, green areas etc. On wetland areas (such as the beds of reed on coasts and lakes, riversides, vegetation on the water features on golf courses, for example, parks, ...) there is lots of cutting to do. MenSe cutter is also suitable for underwater use. With a tilting adaptor the cutting residue may be raked to the shore to be taken away.

MOUNTING

The cutter is attached using an adapter suitable to the customer's basic machine. The basic machine can be any machine equipped with a hydraulic boom. The oil flow sets the limits for which model is best suited for the basic machine (see technical data tables).

OPERATION AND PROPERTIES

The functionality of our cutters is based on reciprocating cutting blades. The cutting takes place between the blade teeth. The blade material is tough 500 HB abrasion resistant steel. Even if the blade tips are rounded by impacts against stones, this will have no influence on the cutting efficiency. there is practically no need for sharpening (even though it can be done using an angle grinder). The blades can be sent for repair at Mense Oy and when their lifetime is over, they can be replaced. If the cutter runs into an iron bar or a similar obstacle, it stops. The cutter's power is insufficient to break the blade. All MenSe cutters can be operated vertically. The robust and simple design ensures long service intervals and hundreds of hours of uninterrupted operation.

MENSE CUTTERS ON YOUTUBE

More videos of the MenSe® cutter can be watched on Youtube channel.

THE BLADES ARE MOVED BY A RELIABLE HYDRAULIC MOTOR

The long-lasting and almost maintenance-free motor ensures excellent reliability. Revolution rate of up to 300 revs per minute. The motor produces a constant smooth and high cutting force for the entire duration of the movement.

EFFICIENCY

The shape and profile of the blades enable efficient cutting. Both blades move resulting to less blockage and the possibility to saw even a bit larger trunks. The two-sided blade cuts to both directions. The working width with the RP10L model is 240 cm and a single cut breaks trunks up to 10 cm diameter. By sawing the maximum cutting diameter is about 15 cm which allows uninterrupted work with even bigger trunks. The cutter's long reach, also behind obstacles, and exact maneuvering enable exact and selective working improving the quality of the job. Optional accessories, i.e. a rotator, a tilt and an extension boom improve the usability even further.

ACCESSORIES

the extension boom improves usability: the blade extends further from under the boom and reaches behind obstacles more conveniently. The extension boom can also be used as an aid when moving the machine. the roughness of surfices cut slows down re-sprouting. If necessary, the clearing and coppice control can be carried out at the same time, using the optionally available pesticide spray piping.

Available spare parts for this product that you can order. If you cannot find part that you're looking for, please contact us.

Most interesting products

Most popular products on the category and products you might find interesting.

Recommended categories

Hand selected product categories what you should check out.